ARCBLUE SERVICES

Supply Chain Optimisation

Make supply chain your competitive advantage

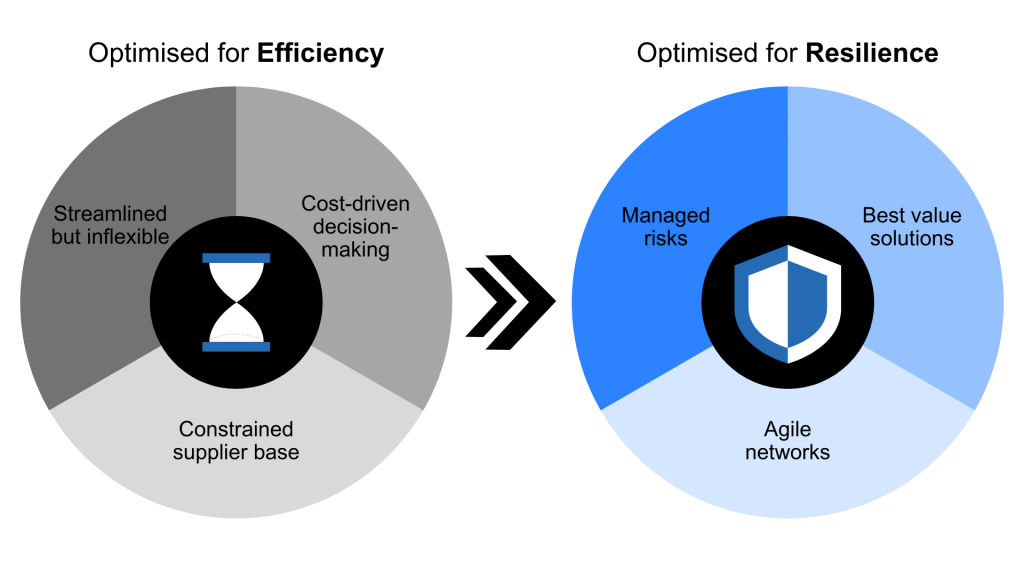

ArcBlue works with organisations to help them build-in resilience, optimise risk management and integrate procurement into their supply chains.

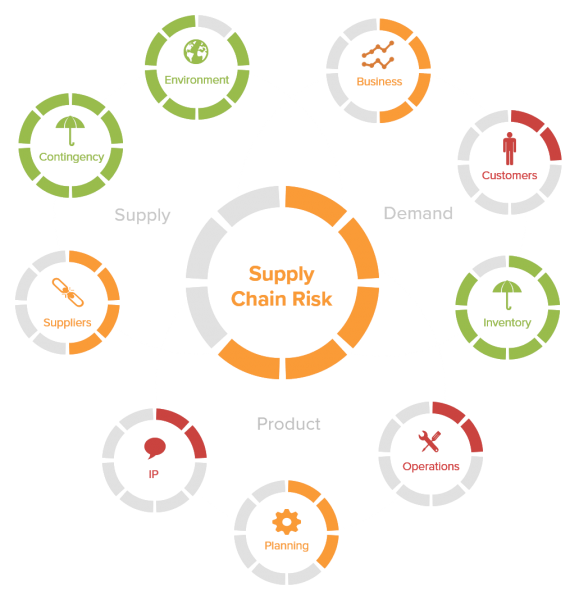

In times of severe supply chain disruption, quick thinking and agile responses are needed to understand supply chain risks and to plan for the future. The first step in any crisis is to understand the extent of the problem – analysing issues across the various tiers of the supply chain to understand the risks, capacity constraints and impact on demand.

Across the Asia Pacific region, many organisations are endeavouring to ‘de-risk’ their supply chains as recent constraints have highlighted the risks of relying heavily on a sole supplier, or on supply from a single location.

Our experienced analysts can assist to optimise supply chain networks using technology such as AI and machine learning to simulate and analyse scenarios, to assist clients to make informed decisions about supply chain design.

ArcBlue has expertise across numerous sectors, industries and geographical locations in achieving real value for companies by using tried and tested tools and programmes adapted by subject matter experts. Our unequalled network of consultants allows us to tap expertise in any supply chain niche.

We see…

- On-shoring, off-shoring, near-shoring, friend-shoring — but what do these all mean?

- Global economic shocks are occurring with ever increasing frequency

- Working in this perpetual uncertainty is becoming business as usual as disruption and volatility continue to define the business environment

- Recent supply chain disruptions have led to a decrease in shareholder returns and company performance

- Navigating supply chain disruptions and recovery challenges compels organisations to reassess strategies

- Supply Chain Agility comes with understanding your supply chains structurally, through an economic lens, and from a risk perspective

- Best practice organisations are utilising advanced technology such as AI, machine learning and digital twins to improve visibility

- Improved visibility enables you to maximise efficiency, maximise optionality, identify & manage risk exposure such as labour laws & modern slavery, Scope 3 & carbon risk and cyber security risk in your supply chain

- An integrated procurement & supply chain provides collaboration and the link between strategy and delivery, enables operational and business efficiencies and provides insights and support to asset strategy and planning

Supply Chain Optimisation Solutions

Right-shoring Solutions

ArcBlue helps clients re-engineer direct goods supply chain to enable growth and manage risk across Asia.

ArcBlue’s “Right-shoring” capability will re-engineer your direct goods supply chain to enable growth and manage risk across Asian supply chains. We drive savings and help businesses de-risk and build resilient supply chains that can rapidly adapt to rising tariffs, geopolitical shifts and escalating shipping costs.

For clients faced with challenging decisions about if, where and when to relocate their supply chains in Asia, we have the expertise to find the best-fit suppliers and ensure balance between cost, risk, supply chain flexibility and diversification. We can provide both strategic recommendations as well as long-term implementation solutions.

With local teams based in Asia, we have experience working in multiple countries in the Asia Pacific region and can assess both incumbents and new potential supplier opportunities. We have knowledge and local understanding to consider varying options including tariffs, freight costs and implications of changing suppliers to provide options and recommendations.

ArcBlue’s ‘Right-Shoring’ solution leverages our expertise across:

- Strategic Sourcing – for clients with constrained and specific supply chain requirements. We help build long-term partnerships that prioritise quality, consistency and innovation with high value, low volume supply base.

- Expansive Sourcing & Negotiation – for direct materials where there is a high volume of potential suppliers. We help identify the right supply chain to enable growth, tailored for your business needs.

- Supply Chain Design & Optimisation – to assist clients to navigate complex regulatory and economic shifts.

Supply Chain Network Optimisation

Advanced technology for optimal supply chain design

Design and manage your supply chain network to make sure that your products flow from suppliers to customers in the most efficient and cost-effective way possible, utilising mathematical modelling, simulations and optimisation algorithms to analyse scenarios and make data-driven decisions. Advanced technologies like machine learning and AI improve decision-making and enable real-time optimisation.

We analyse:

– the location of your facilities and operations

– how you set up your transportation, and

– balancing your inventory to meet customer demands whilst minimising carrying costs.

Our industry-leading digital tools and best practice methodologies help to optimise your network, saving money and improving customer service in the process.

Supply Chain Resilience & Recovery

Helping you understand your current risks and help set up your supply chain for the future

In times of severe supply chain disruption, quick thinking and agile responses are needed to understand supply chain risks and to plan for the future. Our Supply Chain Risk, Resilience & Recovery Methodology helps you to understand where to focus today and how to position your organisation best for the future. The first step in any crisis is to understand the extent of the problem – analysing issues across the various tiers of the supply chain to understand the risks, capacity constraints and impact on demand.

Once understood we need to conduct scenario planning to identify how these issues flow down to other tiers to then deploy contingency measures to minimise further risks. We need to quickly focus on ramping up the supply chain to meet increased demand.

Our Risk, Resilience & Recovery program helps organisations to respond to:

– Current and immediate supply chain risks

– Capacity constraints

– Financial risks

– Inventory shortages through the supply chain

– Supplier financial stress

– Changing demand profiles

Our Risk, Resilience & Recovery methodology helps organisations understand where to focus today and also how to position best for tomorrow.

Our Specialist Team

OUR EXPERIENCE

Capability Programme

INSIGHTS

RESOURCES & DOWNLOADS